19. July 2021

Interview with Christian Maasem I Center Director I Center Connected Industry about the unique 5G test environment for Automated Guided Vehicles driverless transport vehicles at the Smart Logistics Cluster on RWTH Aachen Campus

Is 5G still just theory, possibly with a beta testing status – or have the experts in Aachen advanced further? Christian Maasem could name various fields of application, which, as he carefully words it “definitely make sense, but just haven’t reached their potential as yet”.

Fraunhofer IPT

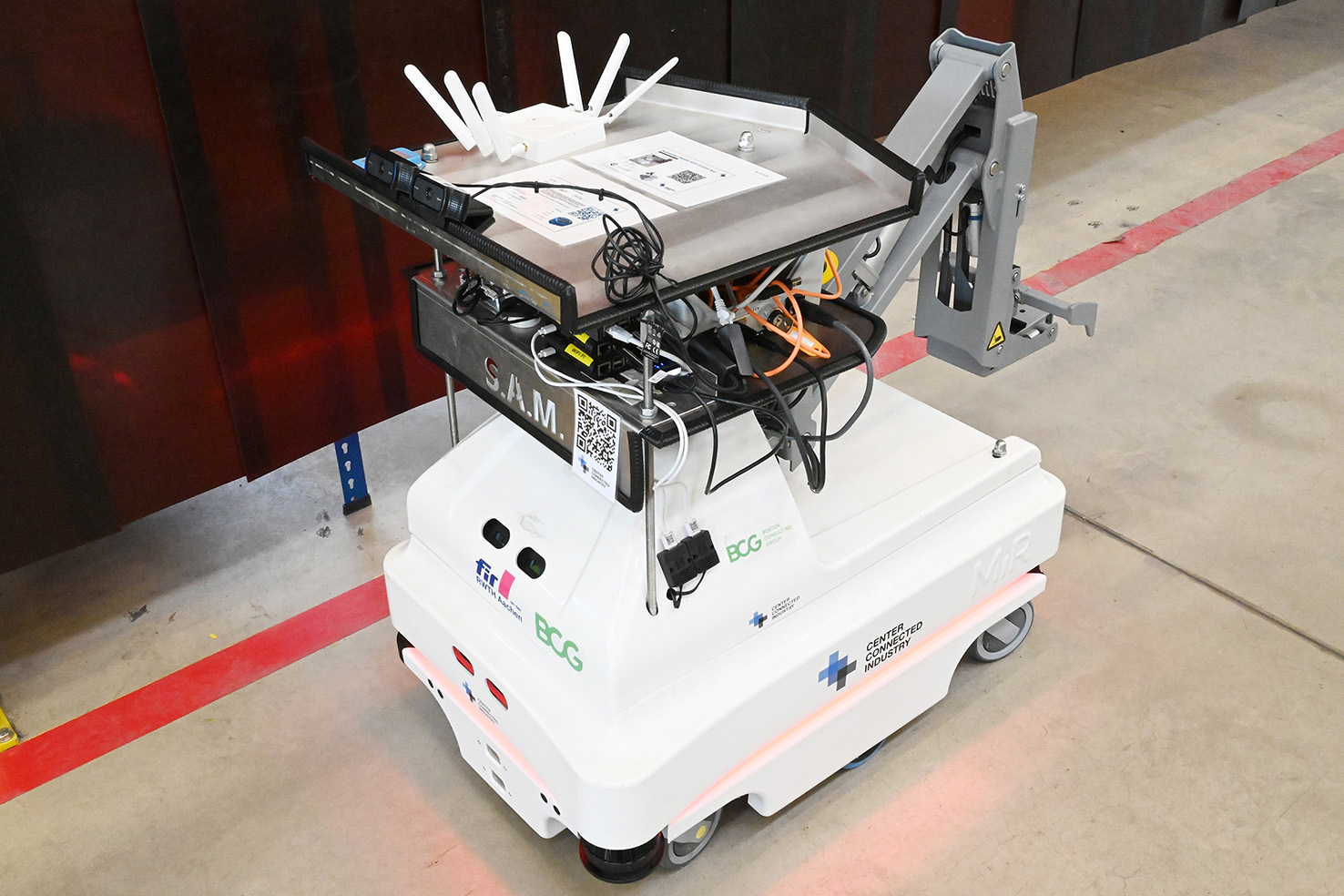

What will get better with 5G? Maasem: “5G allows the capture of enormous amounts of sensor data from transport vehicles and infrastructure in real-time, which is then evaluated close-by – using so-called Edge Computing. Previously, transport vehicles in production and logistics often had to travel at severely limited max. speeds to avoid collisions. With 5G, vehicles can operate with significantly more efficiency and smarter at the same or a higher level of safety.” 5G technology makes real-time a reality.

CCI

DFA

CCI

Deutsche Telekom/T-Systems

Connectivity is an important focus of the work currently being done at the Center and 5G is a key technology in that respect. “5G is so universal and powerful that I can cover almost everything with it”, describes Christian Maasem the benefit of 5G. It relates to the sensors, the automated systems, the software solutions. “Of course, we won’t be focusing solely on that, but 5G is becoming increasingly more frequently the entry point for companies addressing the topic of digitization.”

There are 17 people working on 5G at the center right now, and it additionally gets temporary research personnel support from various RWTH institutes. Christian Maasem: “The mix is really exciting: We get experts from the areas of physics, IT, engineering, economics and even colleagues from social sciences. It really is a colorful mix.” Maasem himself is a physicist and economist. There is one more thing he feels is special in Aachen: The differentiation between the research and industry network. The 5G-Industry Campus Europe project has created a network that is mainly used for research projects, also by the center. It is already now working on and testing the next networks – after 5G. “There are so many options to look at and comparisons to be made, so that we can find the right combination of technologies to suit individual use cases”, explains Maasem.

Maasem about the test-beds at the Demonstration Factory and on the Logistics Campus Eschweiler: “We can replicate concrete use cases of companies and see, what the various technical solutions and benefits look like. This will facilitate a quick and easy data-based decision-making process for the digital transformation in industry.”