Ericsson

Niels König, Department Head Production Metrology at the Fraunhofer Institute for Production Technology IPT, also keeps an eye on this specific objective. “We don’t develop any products. We do believe, however, that in collaboration with industry – and that is exactly what we do – we have a good basis for the development and testing of new products.” On campus, 5G is within reach.

DFA

CCI

Deutsche Telekom/T-Systems

CCI

ika

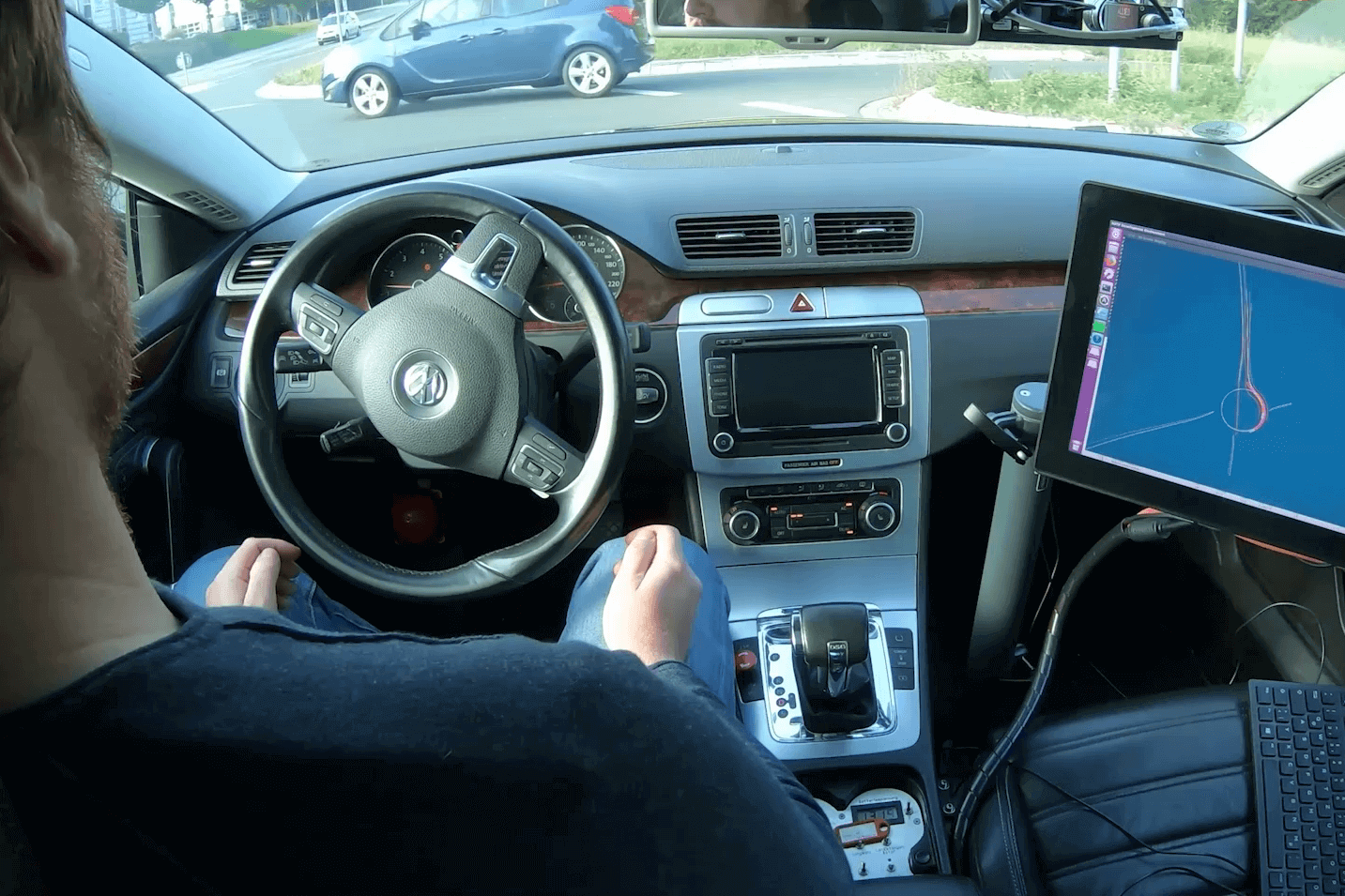

The vehicles that are being tested always have a backup driver on board. Our main concern there is the testing of subfunctions and not a completely automates vehicle guidance. We will look at, for example, lane changes on the freeway involving a slip road. Timo Woopen: “We are still a long way off using testing fields like these without a backup driver.”

ika

Is Germany an innovative location in terms of mobility? “Germany definitely is a place, where a lot of innovative things happen”, says Laurent Klöker, but then he qualifies: “We cannot compare with the US, because the means available there are in an entirely different league.” Nevertheless, he feels that Germany is on the right track in terms of the mobility revolution. Timo Woopen adds a positive mention of the cooperation of German universities as part of the joint project UNICARagil involving eight German universities and eight industrial partners. When it comes to automated driving, a highly complex topic, the field is a lot closer together.

With the 5G research initiative of the Federal Ministry of Transport and Digital Infrastructure, six special allocation decisions were issued to research institutions and universities in 2019. One of the special allocations went to the 5G-Industry Campus Europe initiative. That makes Aachen one of the six 5G model regions selected by the Federal Ministry.

Use cases and research projects that go far beyond previous LTE capabilities are realized as part of the three application profiles:

Paperplane Productions

Stich summarizes the opportunities arising from the close connection between research and industry in Aachen with optimism and confidence: Right now, Aachen is the biggest continuous 5G campus location in Europe. Our advantage is the fact that the big players Ericsson, Telekom and Vodafone are already enrolled members on RWTH Aachen Campus. Which proves: We have an impact beyond Aachen’s city limits, which we don’t even realize sometimes in our day-to-day business.“