6. July 2022

XL Assembly

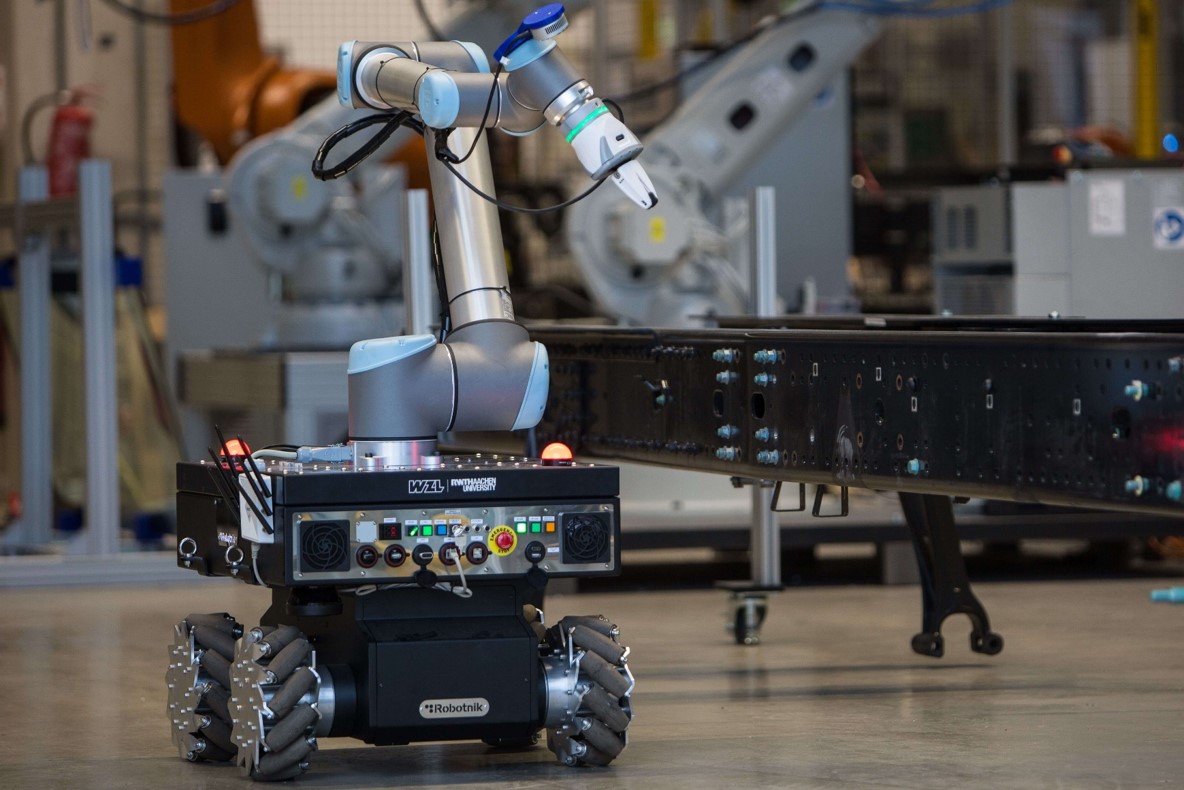

For Center Director Dr. Guido Hüttemann, the flexibility of assembly systems is of particular relevance: “The continued existence of existing production sites depends on whether future assembly systems can contribute to the flexibility and sustainability of production. For us, the assembly of the future is characterized by three terms: lineless, mobile and autonomous.”

A vision for the assembly of the future is currently being developed with 12 companies in an ongoing consortium study. The in-depth analysis of the needs as well as the necessary and available technologies form the basis for further discussion of the topic.

A networking event with presentations and workshops on the topic of “Assembly of the Future” will take place on 26 August 2022. Interested companies will receive further information on the event from mid-July at www.xl-assembly.com.