7. December 2022

Detect machine conditions and process deviations in time to manufacture components in the highest quality and shortest production time. Flexible manufacturing processes adapt to the component and save enormous production costs. Made possible by 5G technology, which is being researched at the 5G Industry Campus Europe. Three years after the start of the project, the German Federal Ministry of Digital Affairs and Transport (BMDV), the VDI and the Fraunhofer Institute for Production Technology IPT invited participants to a celebratory colloquium at Campus Melaten on 29 November 2022.

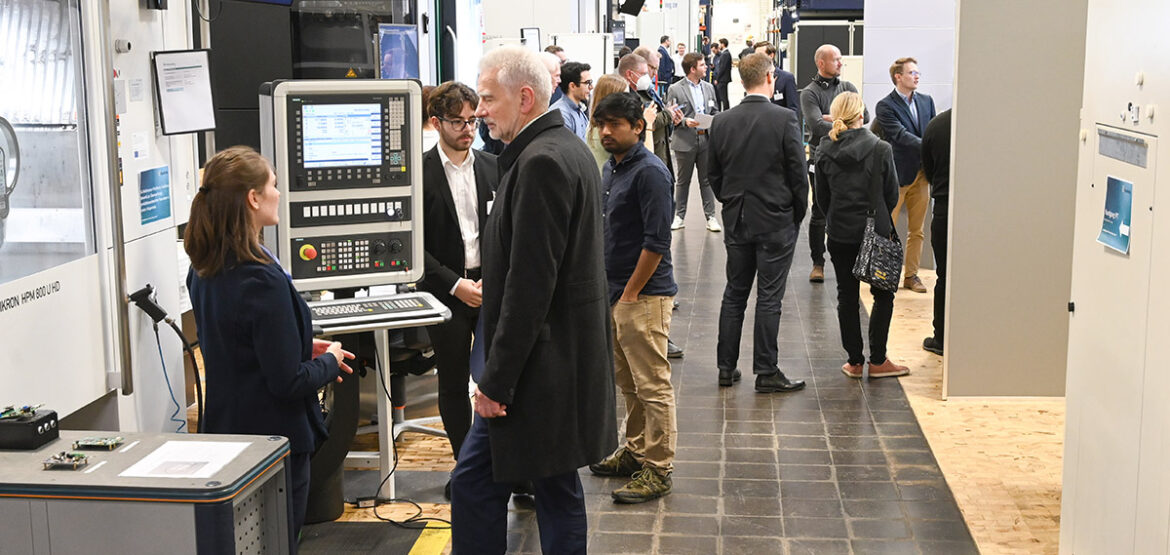

The results of three years of development work were presented at the one-day colloquium: In addition to expert presentations by speakers from the BMDV, RWTH Aachen University, the 5G Alliance for Connected Industries and Automation, the Fraunhofer IPT and Ericsson, the interested company representatives were given exciting insights: During an extensive tour of the 5G Industry Campus Europe, example applications for sensor technology, robotics, logistics and cross-location production chains were presented.

Fraunhofer IPT

Professor Dr.-Ing. Robert Schmitt from Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University speaks to the participants

As coordinator, the Fraunhofer IPT operates a 5G research network on Campus Melaten with equipment from the Swedish mobile communications supplier Ericsson. Together with various partners, concepts and application-ready industrial solutions for networked, adaptive production are being developed: Research is conducted here in an ideal production environment: a landscape of sensor systems and communication technologies that enables an intensive examination of 5G technology. The versatility of the testing possibilities, the cooperation partners within the campus and the proximity to the border also put Aachen in the lead with its 5G Industry Campus Europe.

The 5G Industry Campus Europe is the first location in Europe with a comprehensive 5G network where new applications are researched and tested in production environments under real conditions. Among other things, 5G helps to collect enormous amounts of sensor data from transport vehicles and infrastructure in real time and evaluate it close to the location. With an outdoor network of around 1 km² and a production area of 8,000 m², the 5G network covers the area of Campus Melaten and the entire machine hall of the Fraunhofer IPT. The Melaten campus is one of the largest 5G sites in Europe, and Aachen is one of six model regions in Germany. The current 5G network infrastructure on Campus Melaten includes both indoor radio networks (for example for machine halls, logistics centres, demo factories) and outdoor radio networks (for example for mobile applications such as connected construction or autonomous driving).

Find out more about 5G on Campus Melaten here.